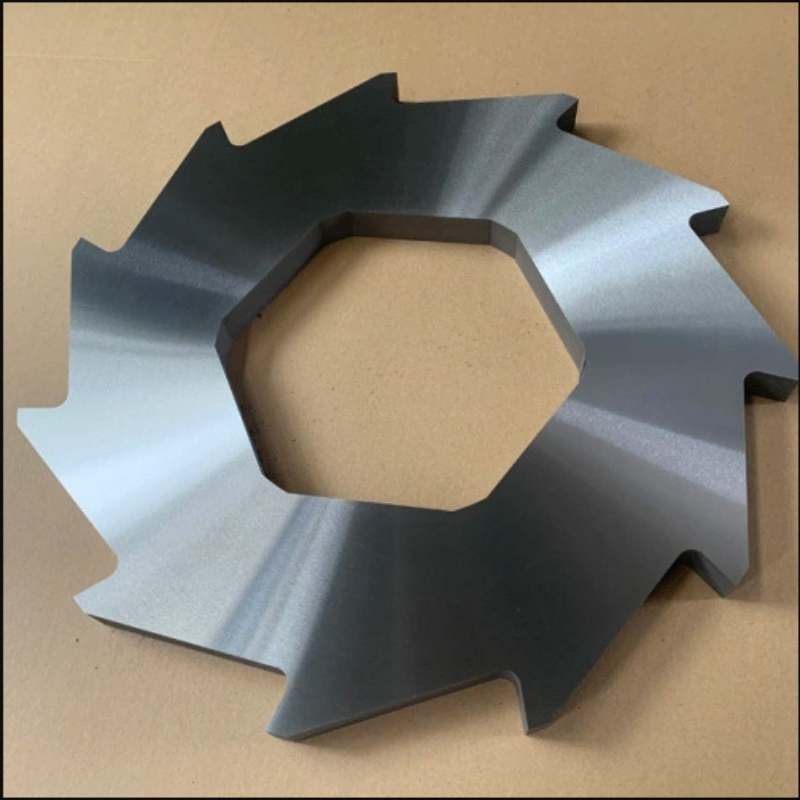

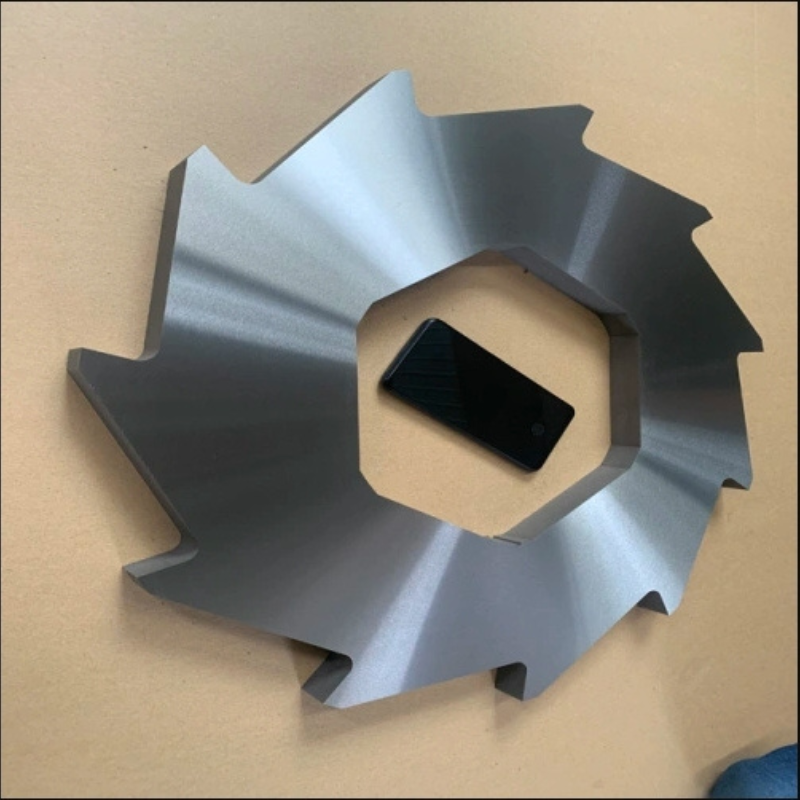

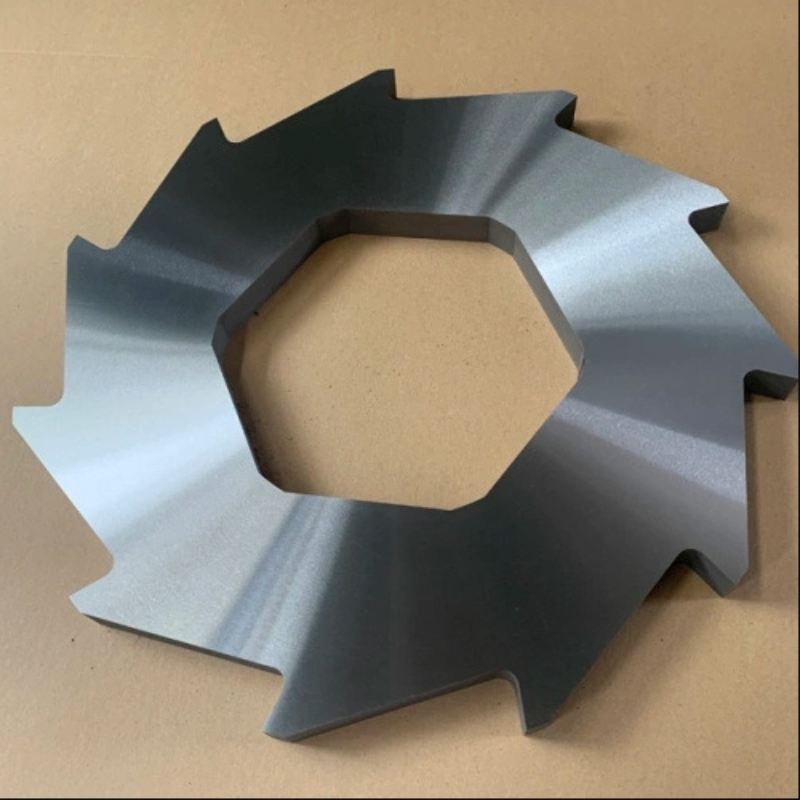

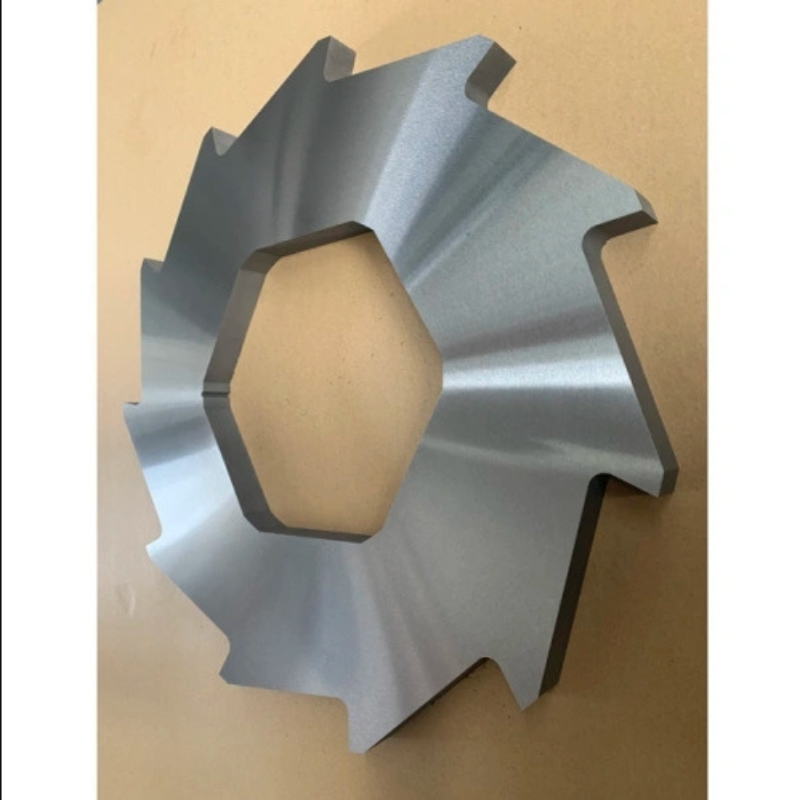

Best Quality Double Shaft Plastic Shredder Blade

Payment Type: L/C,T/T,D/P,D/A,Paypal,D/A

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP,DDP,DDU,Express Delivery

Min. Order: 5 Piece/Pieces

Transportation:Ocean,Land,Air,Express,Express

Port:Tianjin Sea Port,Shanghai Sea Port,Qingdao Sea Port

- Product Details

- After-sale service

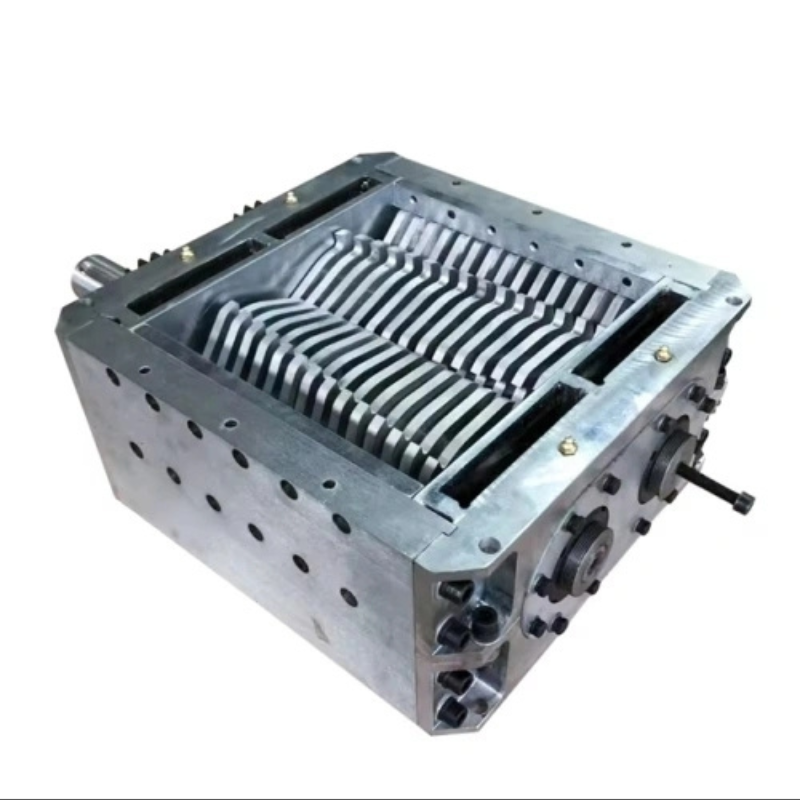

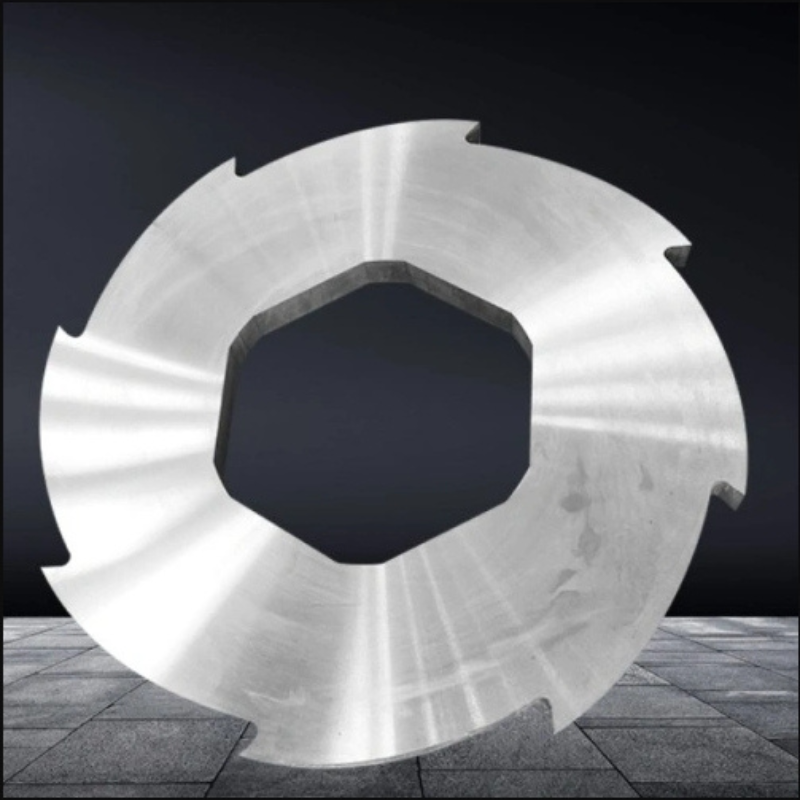

Shredder Blades Description:The Shredder Blade is an important accessory on the shredder. The quality of the shredder blade directly affects the processing cycle of the machine to the waste. According to the classification of the shredder, the shredder blade is divided into single-shaft shredder blade and shredder blade. Multi-shaft shredder Blades. As an important Shredding Knife on the shredder.

Shredder Blades Specification:

Machine model | DS300/400/500/600/800/1000/1500/1200 |

Type | Double dual shaft type shredder case box |

Motor power | Depend on client request |

Output capacity | Depend on client request |

Weight | 300-1500 kg |

Application | DIY Shredder Machine |

Shredder Blades Characteristic:

1. Dual wear resistance: The surface is made of German wear-resistant welding material; The second layer is YG8 particles of

tungsten carbide.

2. Super impact resistance: The surface is made of wear-resistant welding materials welded onto particlesof tungsten carbide,with

a rough welding surface and better biting force; The secondary layer is composed of particlesof tungsten carbide dissolved and

welded on the surface of the substrate, without cracks or peeling, forming a whole.

3. Sharp edge cuts for better cutting effect

4. During use, particlesof tungsten carbidewith sharp edges can have a secondary tearing effect, resulting in better tearing

effect.

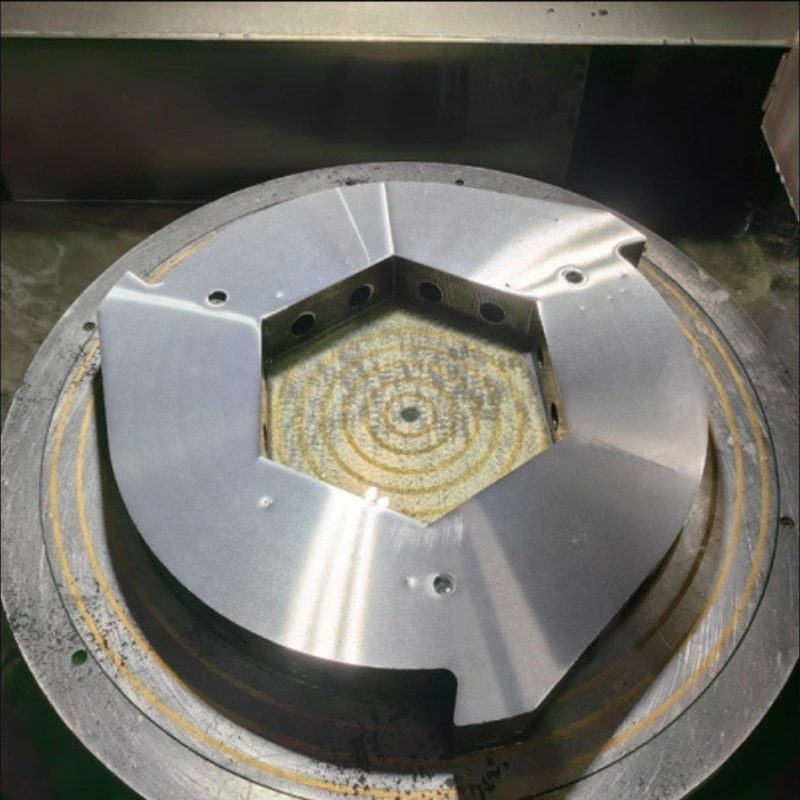

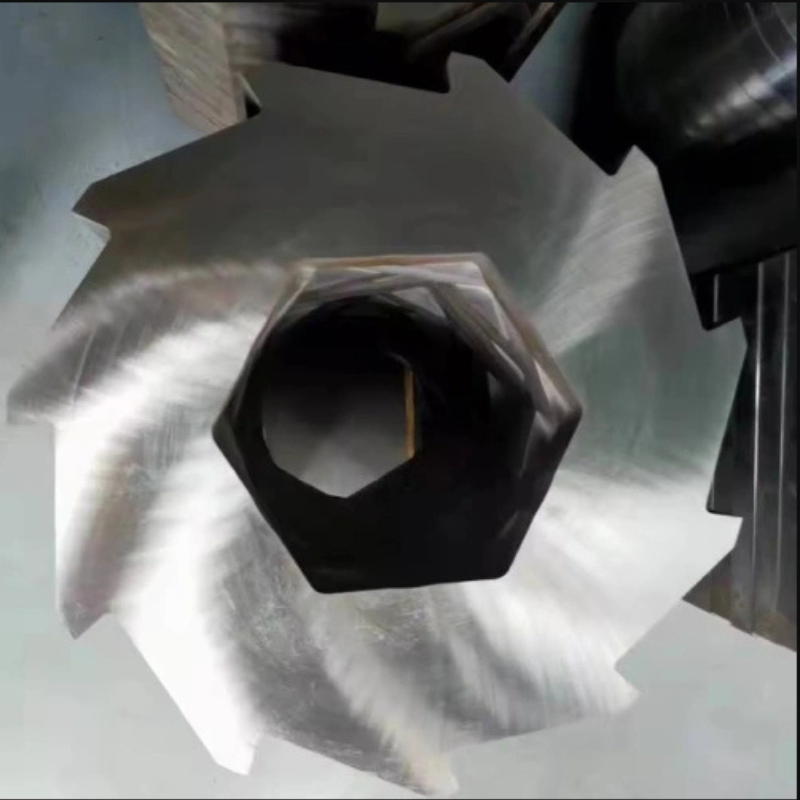

Shredder Blades Production technology:

1. particles of tungsten carbide welding process, which combines particles of tungsten carbide with substrate to form a tungsten carbide wear-resistant layer.

2. Perform secondary welding on the surface of the wear-resistant’stungsten carbide and weld it with German wear-resistant welding rods. Because the surface of the wear-resistant’stungsten carbide is covered with many particles of tungsten carbide,the rough welding surface provides better biting force.

3. After the wear-resistant welding rod is welded, it should be polished to form a sharp cutting edge. The finished hammer blade of tungsten carbidenot only maintains the wear resistance and impact resistance, but also has the ability to cut and tear twice.

| Selling Units | : | Piece/Pieces |

| Package Type | : | Wooden Box |

HSS Double Shaft Metal Tyre Re...

HSS Double Shaft Metal Tyre Re...  Recycling Shredder Blades For ...

Recycling Shredder Blades For ...  Twin Shaft Shredder Blade for ...

Twin Shaft Shredder Blade for ...  High Quality Shredder Blade Fo...

High Quality Shredder Blade Fo...  Customized Double Shaft Metal ...

Customized Double Shaft Metal ...  High Quality Multi-axis shredd...

High Quality Multi-axis shredd...  Double Shaft Shredding Machine...

Double Shaft Shredding Machine...  High Quality Double Shaft Shr...

High Quality Double Shaft Shr...  Double Shaft Shredder Blade fo...

Double Shaft Shredder Blade fo...  Customization Shredder Machine...

Customization Shredder Machine...  Waste Plastic Shredder Blades ...

Waste Plastic Shredder Blades ...  Best Quality Double Shaft Plas...

Best Quality Double Shaft Plas...  High Quality Single-axis shred...

High Quality Single-axis shred...  PET Bottle Recycling Shredder ...

PET Bottle Recycling Shredder ...  Double Shaft Shredder Blades F...

Double Shaft Shredder Blades F...  E-waste Recycling Double Shaft...

E-waste Recycling Double Shaft...  E-Waste Recycling Shredder Bla...

E-Waste Recycling Shredder Bla...  Waste Wood Shredder Blade With...

Waste Wood Shredder Blade With...  Double Shaft Shredder Blade fo...

Double Shaft Shredder Blade fo...  Biomass Double Shaft Shredding...

Biomass Double Shaft Shredding...  Recycle Shredder Blade For Do...

Recycle Shredder Blade For Do...  Tire Rubber Waste Granulator S...

Tire Rubber Waste Granulator S...  High Quality Tyre Cutting Shre...

High Quality Tyre Cutting Shre...  Shredder Cutting Blade for Cru...

Shredder Cutting Blade for Cru...